Innovative products made by our cleaning technologies

Pole housing

Distinctive features:

- Double-shell structure as a consequence of a double-sheet metal construction

- Increased damping and reduced vibration transfer due to micro-friction between the sheet metal layers

Application:

- Engine cooling fan for cars

Manufacturing processes:

- Transfer die

- Cleaning

Diffuser

Distinctive feature:

- Safety-relevant component

Application:

- Driver airbags

Manufacturing processes:

- Multi-stage die

- Cleaning

- Vibratory grinding

Diffuser

Distinctive feature:

- Safety-relevant component

Application:

- Driver airbags

Manufacturing processes:

- Multi-stage die

- Cleaning

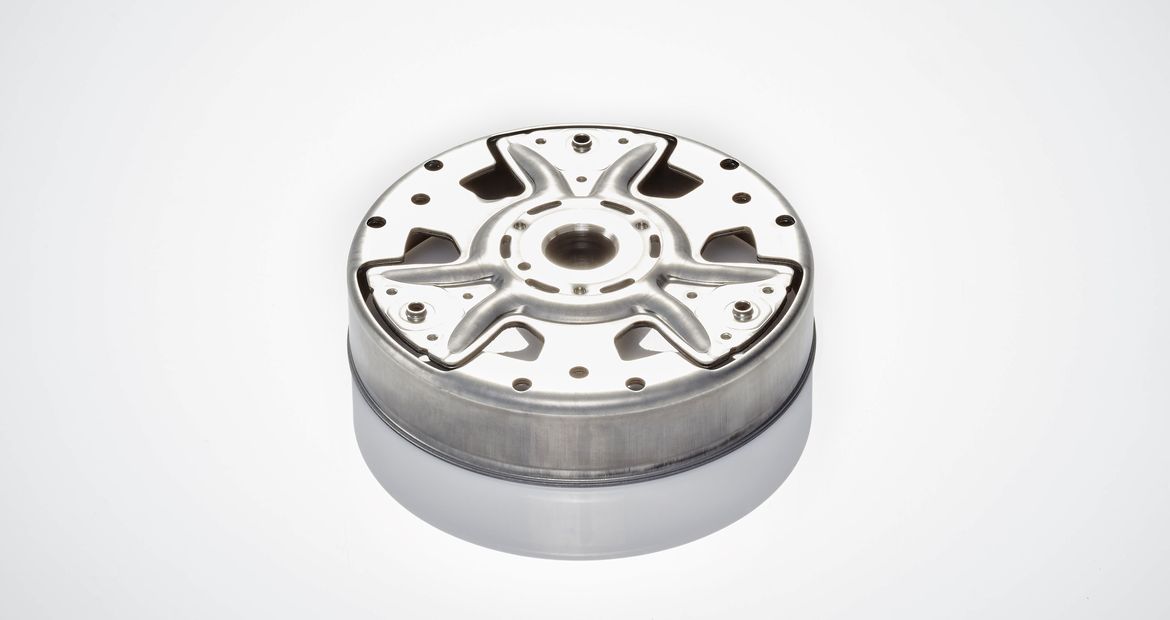

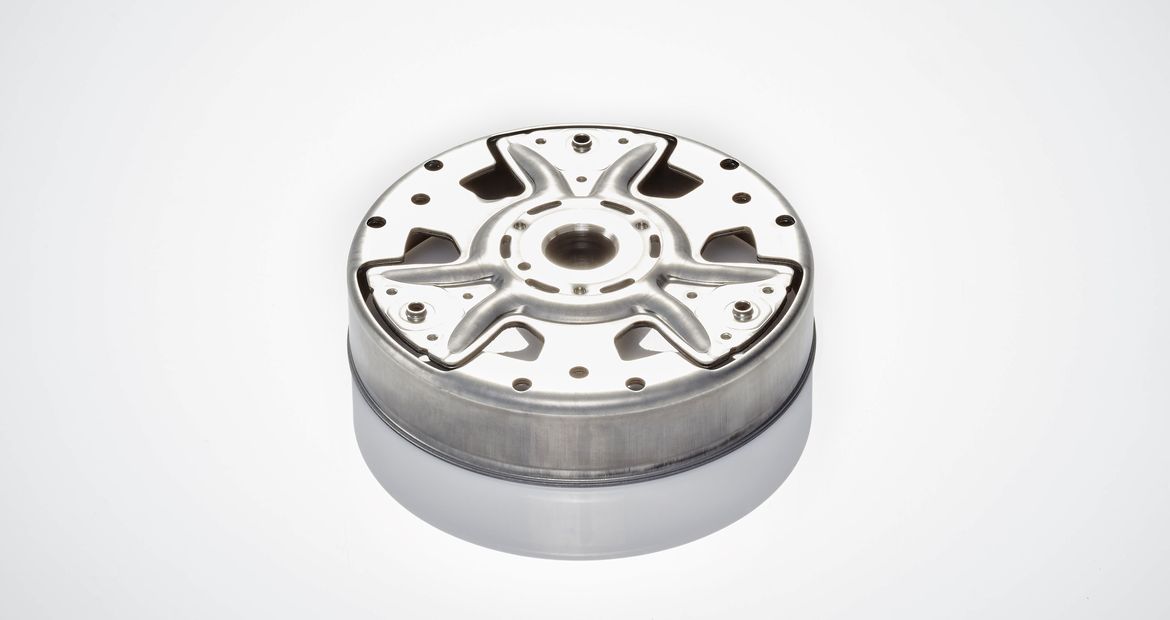

Clutch body

Distinctive feature:

- Welded assembly

Application:

- CVT (Continuously Variable Transmission) gearbox

Manufacturing processes:

- Transfer die

- Vibratory grinding

- Laser welding

- Turning

- Cleaning

Synchronizer ring

Distinctive features:

- Substitution of sintered components

- Locking teeth with press-formed synchronizer spline on the outer diameter

- Fully-automated camera inspection

Application:

- Transmission synchronization

Manufacturing processes:

- Transfer die

- Vibratory grinding

- Cleaning

- Camera inspection

Synchronizer ring

Distinctive features:

- Locking teeth with press-formed synchronizer spline on the outer diameter

- Partially interrupted inner diameter tabs

- Fully-automated camera inspection

Application:

- Transmission synchronization

Manufacturing processes:

- Transfer die

- Vibratory grinding

- Cleaning

- Camera inspection

Intermediate ring

Distinctive features:

- Gas nitriding of the component as protection against wear

- Fully-automated camera inspection

Application:

- Transmission synchronization

Manufacturing processes:

- Transfer die

- Cleaning

- Gas nitriding

- Vibratory grinding

- Camera inspection

ABS housing

Distinctive features:

- Polygon shaped Housing design adapted to the utilized magnet design

Application:

- Anti-lock braking system (ABS)

Manufacturing processes:

- Multi-stage press die

- Cleaning

Control unit housing

Distinctive features:

- Deep-drawn aluminum

- High surface requirements in terms of cleanliness, roughness and impermeability

Application:

- Housing base for electronic control units

Manufacturing processes:

- Transfer die

- Cleaning

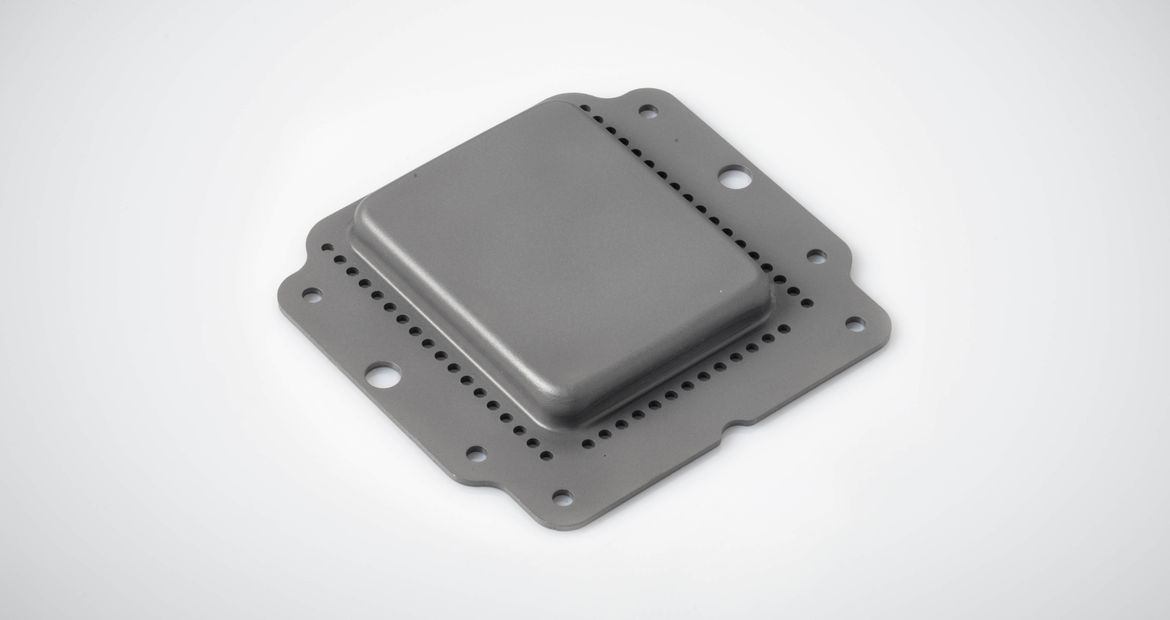

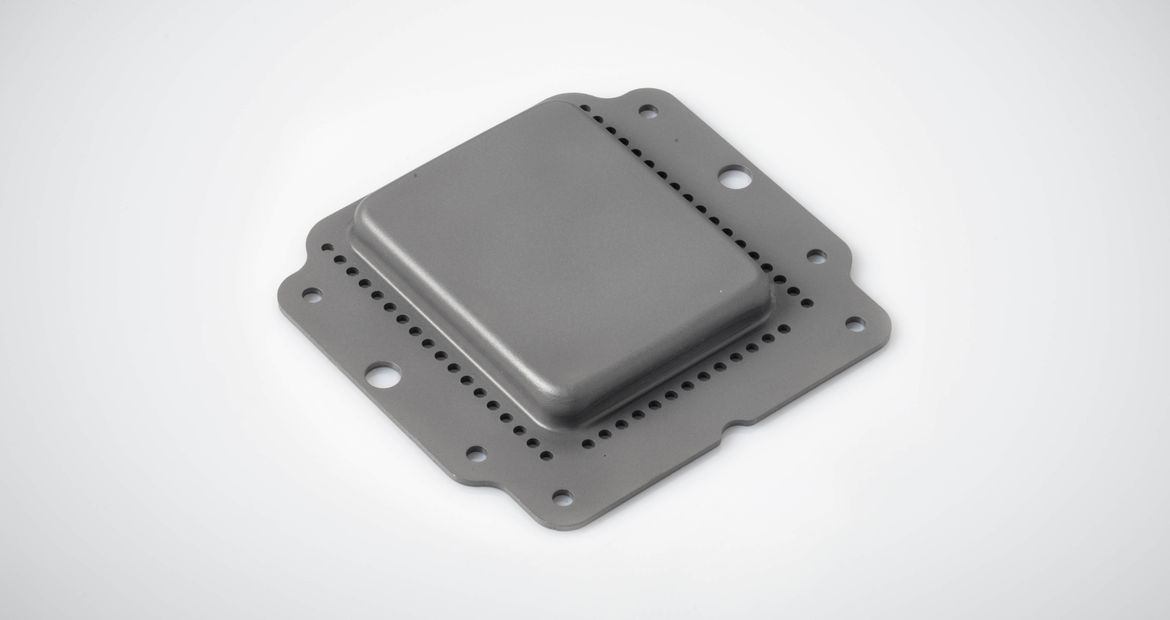

Housing cover

Distinctive features:

- Deep-drawn aluminum

- High surface requirements in terms of cleanliness, roughness and impermeability

Application:

- Housing cover for electronic control units

Manufacturing processes:

- Progressive die

- Cleaning

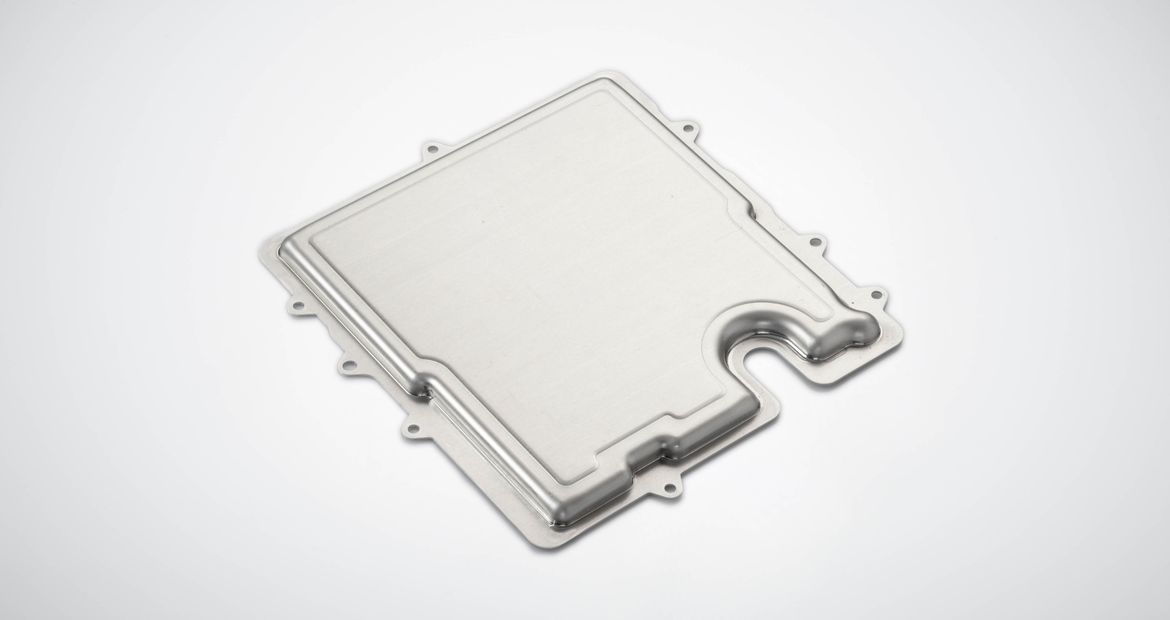

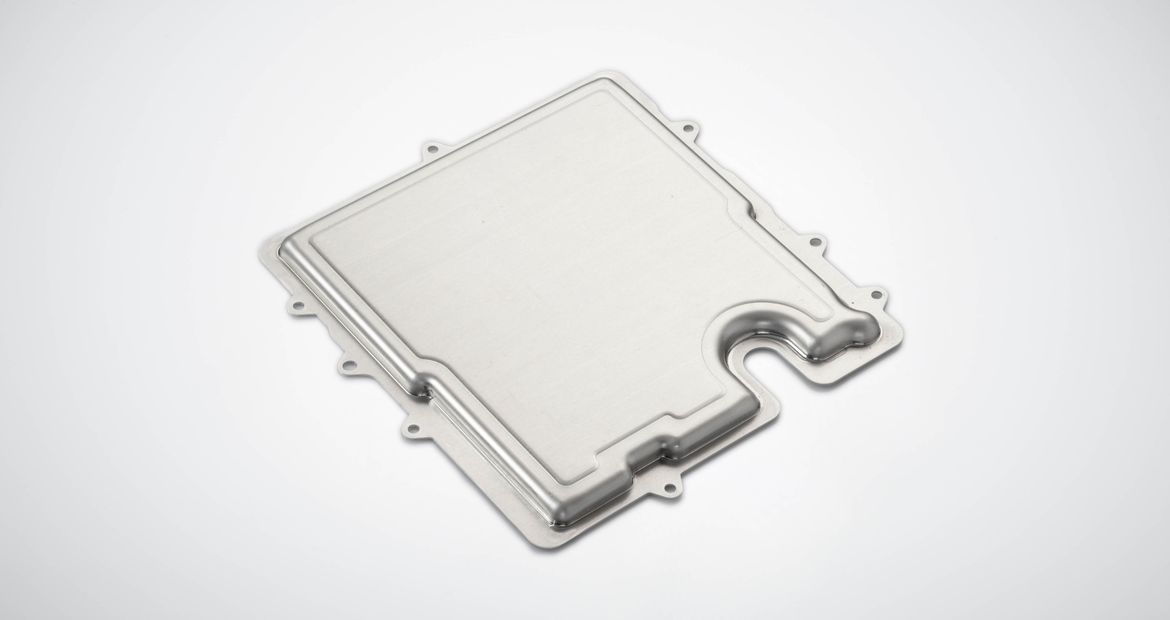

Base plate

Distinctive features:

- High-precision stamping geometries for the subsequent welding process

- Great demands on the shear zone and fracture pattern

Application:

- Base plate for the hermetically sealed transmission control units

Manufacturing processes:

- Progressive dies

- Precleaning

- Vibratory grinding

- Cleaning

Manifold for AC Evaporator

Distinctive features:

- Double-chamber design by rotary bending in the transfer die

- Braze clad aluminum

Application:

- Car air conditioners

Manufacturing processes:

- Transfer die

- Cleaning

- Fully-automated assembly with covers and partitions in various configurations

Motor housing

Distinctive feature:

- Deep drawing of extensive wall thicknesses

Application:

- Small motors for industrial applications

Manufacturing processes:

- Multi-stage press die

- Cleaning

Bearing cover

Distinctive features:

- Precise roller bearing mount for motor shaft

- One-piece design with fastening tabs in the cylindrical wall areas

Application:

- Bearing cover for ebike drive systems

Manufacturing processes:

- Progressive die

- Cleaning

Oil dam

Distinctive feature:

- Material thickening as basis for machining

Application:

- Automatic transmissions

Manufacturing processes:

- Transfer die

- Metal-cutting machining

- Cleaning

Pressure vessel

Distinctive features:

- Tapered diameter at housing opening

- Impermeability requirements

Application:

- Airbag generator on passenger side

Manufacturing processes:

- Multi-stage die

- Burnishing

- Cleaning

Stator housing

Distinctive features:

- Double-shell structure as a consequence of a double-sheet metal construction

- Increased damping and reduced vibration transfer due to micro-friction between the sheet metal layers

Application:

- Electric motor for plug-in hybrid drives

Manufacturing processes:

- Transfer die

- Cleaning

- Laser marking with DMC code

Connection sleeve

Distinctive features:

- Brazed clad aluminum

- Asymmetrical forming

- Sealing seat with tight tolerance

- High roughness requirement of Ra 2.5

Application:

- Connection piece for car heating systems

Manufacturing processes:

- Multi-stage press die

- Cleaning

Drive plate

Distinctive feature:

- Extensive shear zone proportion

Application:

- Hybrid dual-clutch transmissions

Manufacturing processes:

- Transfer die

- Cleaning

Drive plate

Distinctive feature:

- Extensive shear zone proportion

Application:

- Hybrid dual-clutch transmissions

Manufacturing processes:

- Transfer die

- Cleaning

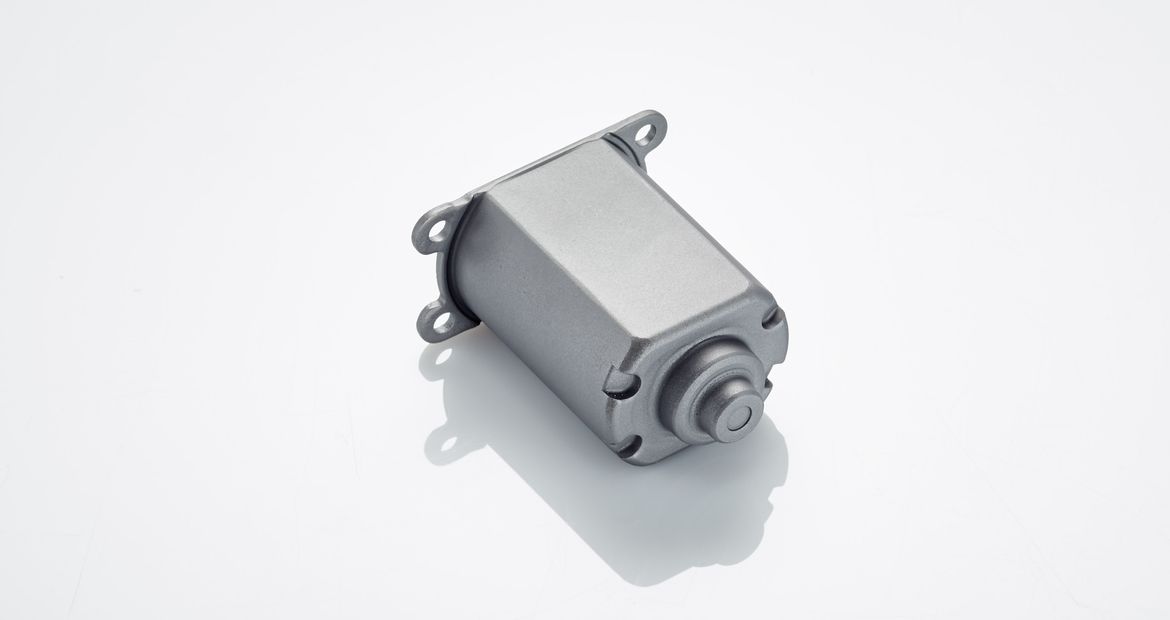

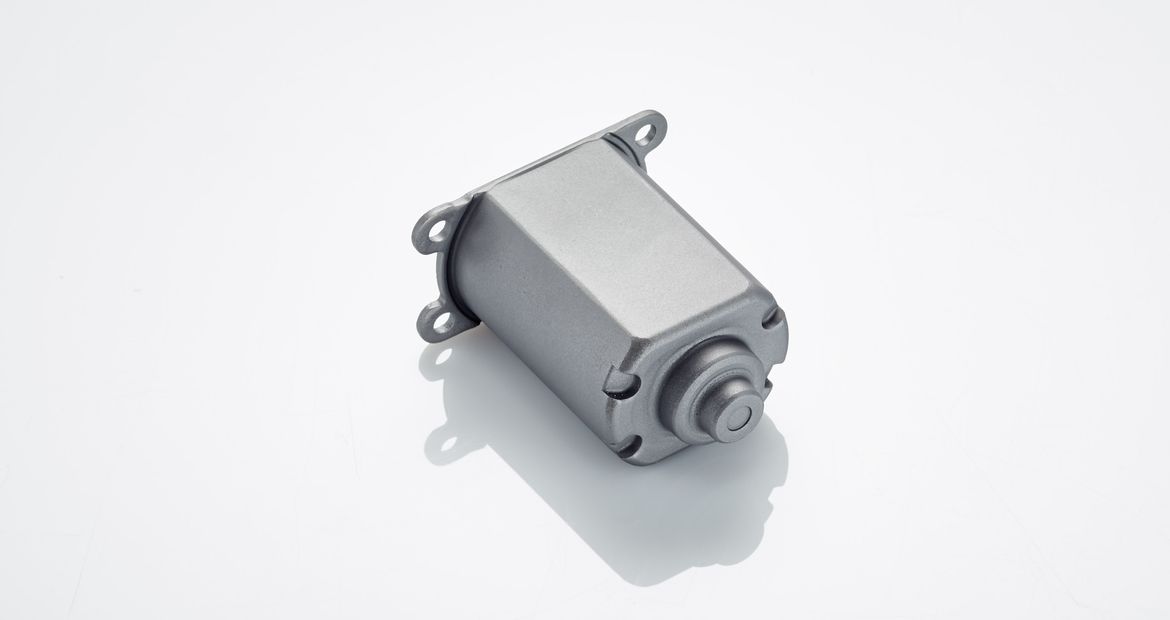

Magnet housing

Distinctive features:

- Welded assembly

- Fully-automated chip-removal machining

Application:

- Camshaft phasers

Manufacturing processes:

- Multi-stage press die

- Machine processing

- Cleaning

- Laser welding

Heat shield

Distinctive feature:

- Material used: Stainless steel

Application:

- Heat shield for a control unit in turbochargers

Manufacturing processes:

- Multi-stage die

- Cleaning

Pressure plate

Distinctive feature:

- Press-formed geometry of apply ring fingers

Application:

- Pressure plate in hybrid transmissions

Manufacturing processes:

- Transfer die

- Cleaning

Heat shielding plate

Distinctive feature:

- Stainless steel

Application:

- Thermal shielding

Manufacturing processes:

- Multi-stage die

- Cleaning

Flat motor housing

Distinctive features:

- Optimization of the operating weight achieved by the exceptional design of the plate

- Special drawing process to optimize wall thicknesses to accommodate the magnetic flux

Application:

- Electric motor housings

Manufacturing processes:

- Transfer die

- Cleaning

Rotor housing

Distinctive feature:

- Welding assembly

Application:

- Motor housings for wet & dry hardfloor cleaners

Manufacturing processes:

- Stamping individual components in a progressive die or transfer die

- Cleaning

- Semi-automatic assembly production applying laser welding technology

-

iPole housing

Distinctive features:

- Double-shell structure as a consequence of a double-sheet metal construction

- Increased damping and reduced vibration transfer due to micro-friction between the sheet metal layers

Application:

- Engine cooling fan for cars

Manufacturing processes:

- Transfer die

- Cleaning

-

iDiffuser

Distinctive feature:

- Safety-relevant component

Application:

- Driver airbags

Manufacturing processes:

- Multi-stage die

- Cleaning

- Vibratory grinding

-

iDiffuser

Distinctive feature:

- Safety-relevant component

Application:

- Driver airbags

Manufacturing processes:

- Multi-stage die

- Cleaning

-

iClutch body

Distinctive feature:

- Welded assembly

Application:

- CVT (Continuously Variable Transmission) gearbox

Manufacturing processes:

- Transfer die

- Vibratory grinding

- Laser welding

- Turning

- Cleaning

-

iSynchronizer ring

Distinctive features:

- Substitution of sintered components

- Locking teeth with press-formed synchronizer spline on the outer diameter

- Fully-automated camera inspection

Application:

- Transmission synchronization

Manufacturing processes:

- Transfer die

- Vibratory grinding

- Cleaning

- Camera inspection

-

iSynchronizer ring

Distinctive features:

- Locking teeth with press-formed synchronizer spline on the outer diameter

- Partially interrupted inner diameter tabs

- Fully-automated camera inspection

Application:

- Transmission synchronization

Manufacturing processes:

- Transfer die

- Vibratory grinding

- Cleaning

- Camera inspection

-

iIntermediate ring

Distinctive features:

- Gas nitriding of the component as protection against wear

- Fully-automated camera inspection

Application:

- Transmission synchronization

Manufacturing processes:

- Transfer die

- Cleaning

- Gas nitriding

- Vibratory grinding

- Camera inspection

-

iABS housing

Distinctive features:

- Polygon shaped Housing design adapted to the utilized magnet design

Application:

- Anti-lock braking system (ABS)

Manufacturing processes:

- Multi-stage press die

- Cleaning

-

iControl unit housing

Distinctive features:

- Deep-drawn aluminum

- High surface requirements in terms of cleanliness, roughness and impermeability

Application:

- Housing base for electronic control units

Manufacturing processes:

- Transfer die

- Cleaning

-

iHousing cover

Distinctive features:

- Deep-drawn aluminum

- High surface requirements in terms of cleanliness, roughness and impermeability

Application:

- Housing cover for electronic control units

Manufacturing processes:

- Progressive die

- Cleaning

-

iBase plate

Distinctive features:

- High-precision stamping geometries for the subsequent welding process

- Great demands on the shear zone and fracture pattern

Application:

- Base plate for the hermetically sealed transmission control units

Manufacturing processes:

- Progressive dies

- Precleaning

- Vibratory grinding

- Cleaning

-

iManifold for AC Evaporator

Distinctive features:

- Double-chamber design by rotary bending in the transfer die

- Braze clad aluminum

Application:

- Car air conditioners

Manufacturing processes:

- Transfer die

- Cleaning

- Fully-automated assembly with covers and partitions in various configurations

-

iMotor housing

Distinctive feature:

- Deep drawing of extensive wall thicknesses

Application:

- Small motors for industrial applications

Manufacturing processes:

- Multi-stage press die

- Cleaning

-

iBearing cover

Distinctive features:

- Precise roller bearing mount for motor shaft

- One-piece design with fastening tabs in the cylindrical wall areas

Application:

- Bearing cover for ebike drive systems

Manufacturing processes:

- Progressive die

- Cleaning

-

iOil dam

Distinctive feature:

- Material thickening as basis for machining

Application:

- Automatic transmissions

Manufacturing processes:

- Transfer die

- Metal-cutting machining

- Cleaning

-

iPressure vessel

Distinctive features:

- Tapered diameter at housing opening

- Impermeability requirements

Application:

- Airbag generator on passenger side

Manufacturing processes:

- Multi-stage die

- Burnishing

- Cleaning

-

iStator housing

Distinctive features:

- Double-shell structure as a consequence of a double-sheet metal construction

- Increased damping and reduced vibration transfer due to micro-friction between the sheet metal layers

Application:

- Electric motor for plug-in hybrid drives

Manufacturing processes:

- Transfer die

- Cleaning

- Laser marking with DMC code

-

iConnection sleeve

Distinctive features:

- Brazed clad aluminum

- Asymmetrical forming

- Sealing seat with tight tolerance

- High roughness requirement of Ra 2.5

Application:

- Connection piece for car heating systems

Manufacturing processes:

- Multi-stage press die

- Cleaning

-

iDrive plate

Distinctive feature:

- Extensive shear zone proportion

Application:

- Hybrid dual-clutch transmissions

Manufacturing processes:

- Transfer die

- Cleaning

-

iDrive plate

Distinctive feature:

- Extensive shear zone proportion

Application:

- Hybrid dual-clutch transmissions

Manufacturing processes:

- Transfer die

- Cleaning

-

iMagnet housing

Distinctive features:

- Welded assembly

- Fully-automated chip-removal machining

Application:

- Camshaft phasers

Manufacturing processes:

- Multi-stage press die

- Machine processing

- Cleaning

- Laser welding

-

iHeat shield

Distinctive feature:

- Material used: Stainless steel

Application:

- Heat shield for a control unit in turbochargers

Manufacturing processes:

- Multi-stage die

- Cleaning

-

iPressure plate

Distinctive feature:

- Press-formed geometry of apply ring fingers

Application:

- Pressure plate in hybrid transmissions

Manufacturing processes:

- Transfer die

- Cleaning

-

iHeat shielding plate

Distinctive feature:

- Stainless steel

Application:

- Thermal shielding

Manufacturing processes:

- Multi-stage die

- Cleaning

-

iFlat motor housing

Distinctive features:

- Optimization of the operating weight achieved by the exceptional design of the plate

- Special drawing process to optimize wall thicknesses to accommodate the magnetic flux

Application:

- Electric motor housings

Manufacturing processes:

- Transfer die

- Cleaning

-

iRotor housing

Distinctive feature:

- Welding assembly

Application:

- Motor housings for wet & dry hardfloor cleaners

Manufacturing processes:

- Stamping individual components in a progressive die or transfer die

- Cleaning

- Semi-automatic assembly production applying laser welding technology