Core competences: Always innovative and at the technological forefront

From the development of the product all the way to series production

1 Tool design and Tool shop

- highly-qualified employees

- Vertical intergration of the entire in-house value-added chain

- Fully-equipped state-of-the-art machinery

- Prototype production

- Tool testing on trial press

2 Progressive compound tool manufacturing

With this type of production, various process steps such as punching or piercing, bending, deep drawing, coining or embossing are carried out with a single tool. The development and construction effort is slightly higher than with other processes. However, due to the greater productivity, it pays off rather quickly when larger quantities are involved.

- High strokes

- 40 - 1,000 tons

- Table length up to 4,000 mm

- Simplyfied tool setup

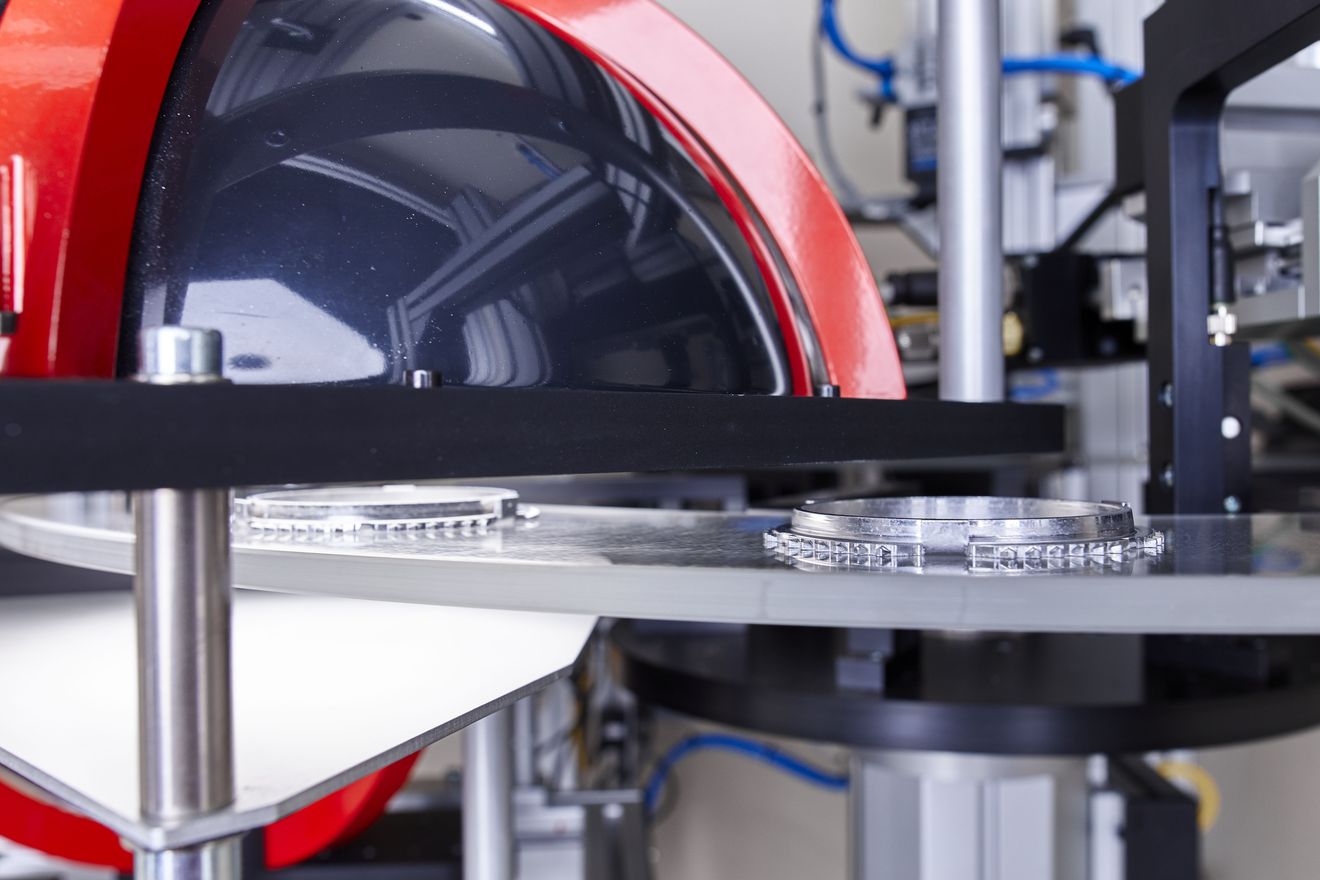

3 Transfer press manufacturing

Classic transfer press production is the first choice when medium-sized forming is required or when combinations with horizontal machining such as drilling or embossing are required.

- 400 - 1,500 tons

- Table length up to 4,200 mm

- Drawing heights of up to 150 mm possible

- Combined process of progressive and transfer press technology

- Change of processing direction possible

4 Transfer press production / Deep drawing manufacturing

When it comes to high forming ratios, tight tolerances and ready-made solutions, deep drawing performed on transfer presses is generally technically and economically the unbeatable way to go. Formed deep-drawn parts can be manufactured very efficiently fully automatically.

- 350-500 tons

- Table length up to 3,600 mm

- Drawing heights capable of 140 mm possible

- Favorable operating weight

- Individual independent tools

- Change of processing direction possible

5 Individual procedures

ERNST is also content to use unique and extraordinary solutions to bring your desired part geometry into the best possible shape – we do not restrict ourselves to simply applying the classic methods. Our experienced engineers have long proven their aptitude for understanding complex technological correlations by creating countless solutions for numerous apparently "impossible" parts. Take us up on the challenge!

- An excellent example is our cold forging technology performed in a transfer press

6 CNC machining technology

- Two-spindle horizontal CNC lathes and vertical CNC lathes

- Fully-automated

- High-added value

- The process chain is entirely in-house

- No interface losses

7 Welding technology

- Laser welding

- Pressure welding

- Projection welding

- MAG welding

- In-house process chain

- No interface losses

- Increased added value

- Know-how

8 Cleaning technology

- PER cleaning

- Aqueous cleaning

- Pass-through washing installations

- Alcohol-based system

- Our own residual dirt analysis lab

9 Our internationally integrated manufacturing network

Standardized technology, processes and competences at all of the ERNST Group’s four locations worldwide.

- Uniform processes

- Established know-how transfer

- Reduced interfaces through international responsibility

- Identical manufacturing presses

- Consistent cleaning techniques

- Standardized tool concept

- CNC machining technology

10 Value-added chain

Processes certified according to international standards ensure optimal supply chains

The ERNST Group optimally integrates into your value-added chain anywhere in the world by bundling and linking the manufacturing processes for metal-formed parts from the development stages to series production including all of the necessary follow-up processes through to finely coordinated logistics.

Modern process organization, combined with continuous improvement processes, ensure that your orders at ERNST are efficiently handled at a very high international level.

Thus, your collaboration with the ERNST Group contributes to increasing your overall added value.

11 Third party services

We put everything together according to your individual requirements

If desired, we implement and manage further processing of your formed parts in cooperation with our service partners who are experienced industry leaders. It goes without saying that we ensure that all third party services meet the same high-quality standards as all of our in-house services.

We are therefore able to offer you even more extensive service packages for your formed parts and assemblies. This facilitates the process for you and in additional, increases your added value.

Here are just some of the conceivable third party services:

- Coating

- Heat treatment

- Components for assemblies

ERNST accompanies you on your route from development to series production

Customer desires

- Sales

- Initial feasibility study and analysis

- Quotation or preliminary offer

Concept phase

- Simultaneous engineering

- Design studies

- Simulation

- Rapid prototyping

Project management

- Feasibility study

- Prototyping including water jet cutting capabilities among others

- Functional testing performed by the customers

Binding quotation

Production planning

- Process definition with final feasibility study and analysis

- Determination of the manufacturing concepts

• Progressive dies

• Transfer dies

• Multi-stage press dies

• Special forming dies - Design

- Tool manufacturing

• Manufacturing equipment e.g. high-speed milling or CNC technology

Sampling

- Production of initial samples under series conditions

- Implementation of the production part approval process (PPAP) and documentation

- PPAP approval by customers