All around the world with precise shapes

The ERNST Group since 1970 until the present day

2019: New hall with underfloor scrap-disposal system at the headquarters in Oberkirch

- A new 3,100 m² production hall in Oberkirch is completed. Noteworthiness: Scrap is transported underground directly to the adjacent scrap hall

- New large press intended for the new e-mobility projects which has a pressure range to 1,500 tons, an electronic 3-axis transfer system, and an automatic coil changer among other things

- A new 5-axis CNC-milling machine capable of manufacturing individual tool parts for larger products with extremely high precision was added to our range of machinery

2018: IATF 16949 certified at every ERNST site

- IATF 16949 is uniformly recognized worldwide. The automotive industry quality management standard has been in effect at every ERNST site since March 2018

ERNST China

- Doubling of the area by way of a 2,800 m2 extension

- New 1,000 ton press

- Plans for a further extension will be specified

ERNST USA

- Significant investments made to social areas of the company

- Construction of scrap recovery building to ensure environmental objectives are met

ERNST France

- Largest investment at the Niederbronn-les-Bains site: Construction of a 1,400 m² logistics building including an administrative wing for the dispatch office as well as for the production control department

2017: Processes at ERNST USA reorganized

- Reconstruction at ERNST USA for enhanced processes: Fundamental process optimization from incoming goods to dispatch doubles the area by adding 2,800 m2 of floor space

2016: Quality and environmental management certified worldwide

- The company recorded the highest number of incoming orders in its history – over EUR 15 million

- Inspected worldwide by TÜV (German Association for Technical Inspection). The Moraine (USA) site received environmental management certification, every ERNST site now has integrated management systems in accordance with ISO TS 16949 (quality) and ISO 14001 (environment)

- Additional space was created for an even higher level of vertical integration. The structural expansion in Oberkirch accommodates subsequent operations such as welding, machining, assembly and mechanical processing

2015: Sales exceed EUR 100 million for the first time

- The ERNST Group generates annual sales of more than EUR 100 million for the first time

- The ERNST Talent Factory: A program for analyzing potential young talent in order to develop and promote them at an early stage to become specialists or managers

- Ernst USA celebrates 10 year anniversary

2014: Premiere for machining at ERNST Germany

- Chipless forming and CNC machining under one roof in Oberkirch for completely new processing options from just one source

- Expansion in the manufacturing field of surface treatment including residual dirt analysis equipment at the headquarters in Oberkirch

2012: Modernized brand with more space in France and premiere for CNC machining at ERNST USA

- ERNST France inaugurates an extension building providing them with 1,200 m² more space

- Modernized ERNST brand identity: New advertising media which give products and companies a suitable platform

- Ernst USA installs CNC machining capabilities as value added option

2011: ERNST China founded

- ERNST enters the Asian market with a subsidiary in Wujiang

2011: Expansion of laser technology in Oberkirch

- Constant expansion: 800 m² of space for logistics and a 1,000 ton transfer press in Oberkirch

- The latest joining technology arrives: ERNST expands the applied laser technology

2010: 40th anniversary

2008 / 2009: Successors Matthias Ernst and Herbert Gieringer take over the leadership responsibilities

- Change of generations: At the age of 75, company founder Egon Ernst hands over the management of the company to his son Matthias Ernst and the long-time General Manager Herbert Gieringer.

- The international financial crisis hits ERNST. Sales slump 50 percent in the 1st quarter of 2009 making reduced working hours necessary for the first time. Fortunately, things soon started to improve again.

- Trade show premiere at "Blech Russia" (An exhibition for sheet metal working) signals opening up towards the East

ERNST USA

- As of January 1, 2009, the ERNST Group takes over all shares in Ernst & Moore

2005 / 2006: ERNST USA establishes collaboration

- Substantial investments in machinery and buildings at every location worldwide

- EUR 63 million sales – three times as much as in 1996

- 530 employees around the globe

ERNST USA

- Merger with the company Moore Quality Tooling operates as ERNST & Moore. All of ERNST’s services can be offered in the USA from this day on due to the identical machinery and processes as in Germany

ERNST Germany

- Extension built for production management and foremen's offices

- New office building

2001 – 2004: The ERNST Group HQ in Germany undergoes substantial expansion

- Surface treatment gets its own building in line with the highest standards

- An additional 1,500 m² of warehouse space for semi-finished goods is constructed

- Acquisition of a neighboring building to expand the tool shop and the apprenticeship workshop

- Production area and range of machinery continue to expand

1998 – 2000: Steadily increasing growth for safety-relevant precision parts

- Mark of confidence: ERNST produces ever more highly-precise safety-relevant parts for airbags

- The production area increases to approximately 10,500 m²

- New transfer presses with up to 5,000 kN are installed

- By the end of 1999, ERNST employed 265 highly-skilled staff members

- ERNST’s export share reaches 29 percent

- Quality management certification according to ISO TS 16949 successfully completed

- Environmental management in accordance with DIN EN ISO 14001 achieved with success

1994 – 1997: Logistics center and ERNST France

- Quality management in compliance with DIN ISO 9001 ff

- Construction of a 1.600 m2 logistics center, purchase of 2.5 hectares of land

- Increased production of technologically sophisticated assemblies and components

- Expansion of the transfer technology

ERNST France

- 1997: Foundation of ERNST S.A.R.L. Découpage – Emboutissage in Niederbronn-les-Bains, Frankreich

1989 – 1993: ERNST becomes a development partner

- CNC technology enlarges capacity in tool manufacturing

- New transfer press with 2,500 kN

- Enhancements in quality management and quality assurance fortify our recognition as a quality supplier

- Expansion of CAD / CAM technology

- ERNST advances to a development partner. The emphasis is placed on product and process development.

- Significant sales growth

- Teamwork along with an incentive-wage program results in a surge of productivity

1983 – 1988: CAD, CIP und SPC move in

- New era for high-quality precision parts owing to the first transfer press

- The development to become a quality supplier is progressing on an unceasing basis

- Company principles define the business development

- The introduction of statistical process control (SPC) is an effective instrument of self-regulation

- CAD technology is integrated into the design process

- Continuous improvement process (CIP) optimizes processes and exploits cost potentials

1970 – 1982: ERNST evolves from being a toolmaker to a manufacturing enterprise

- The company is founded by Egon ERNST. The business objective of the company is to manufacture tools and devices for customers in the stamping industry

- The series production of our own stamped and drawn parts begins in 1974

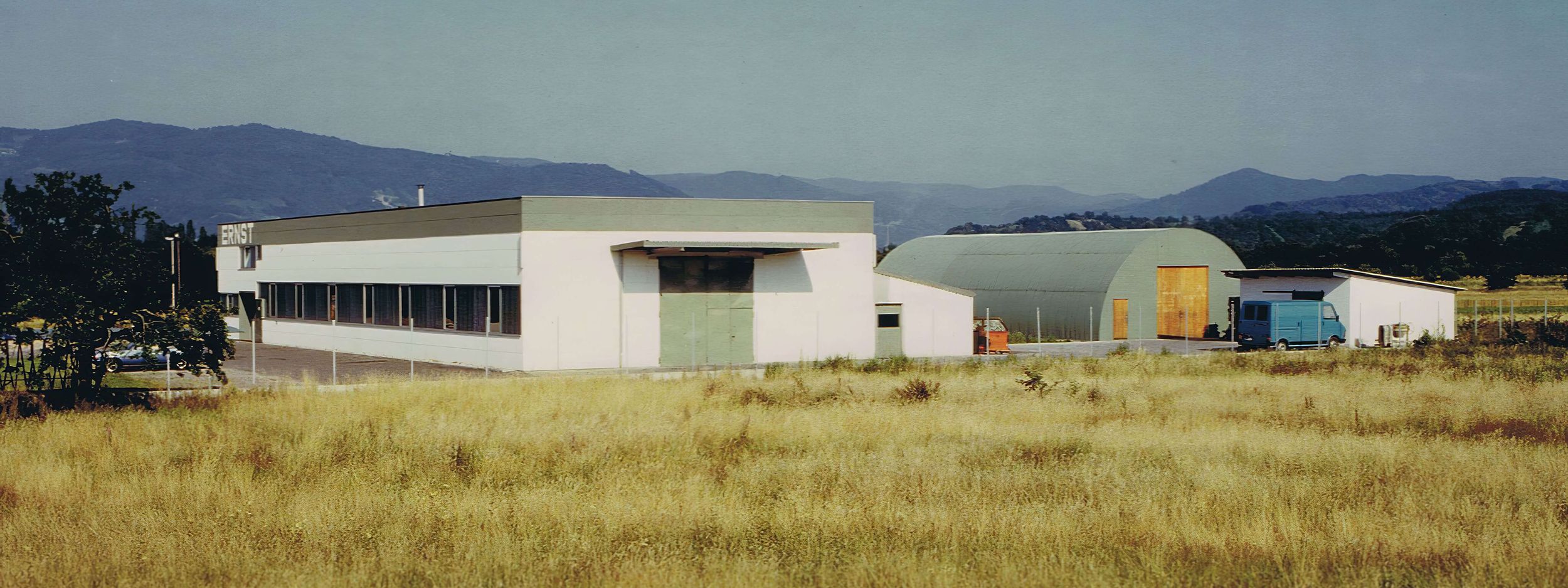

- The first company building is built and occupied in the industrial zone of Oberkirch-Zusenhofen in 1978

- ERNST has been regularly represented at the Hanover Fair since 1979

- Both sales and the number of employees are constantly rising